TOP PERFORMING INDUSTRIES

The 11 industries reporting growth in September - listed in order - are: Petroleum & Coal Products; Apparel, Leather & Allied Products; Electrical Equipment, Appliances & Components; Food, Beverage & Tobacco Products; Paper Products; Nonmetallic Mineral Products; Chemical Products; Plastics & Rubber Products; Miscellaneous Manufacturing; Computer & Electronic Products; and Transportation Equipment.

WHAT RESPONDENTS ARE SAYING …

* “Business continues strong across all market segments.” (Primary Metals)

* “Outlook going forward is cloudy due to concerns from the mortgage market.” (Fabricated Metal Products)

* “Economy appears to be in neutral. Waiting to see if the consumer confidence shows itself for the Christmas season as gasoline prices level off.” (Transportation Equipment)

* “Signs of softening in pace of new orders.” (Miscellaneous Manufacturing)

COMMODITIES REPORTED UP/DOWN IN PRICE and IN SHORT SUPPLY

Commodities Up in Price

Chemicals; Corrugated Containers; Flour (2); Milk; Packaging Materials (2); Polypropylene (2); Soybean Products (4); Sulfuric Acid; and Wheat.

Commodities Down in Price

Aluminum Extrusions; Natural Gas (3); Nickel (3); and Stainless Steel.

Commodities in Short Supply

Sulfuric Acid (2) is the only commodity listed in short supply.

SEPTEMBER 2007 MANUFACTURING INDEX SUMMARIES

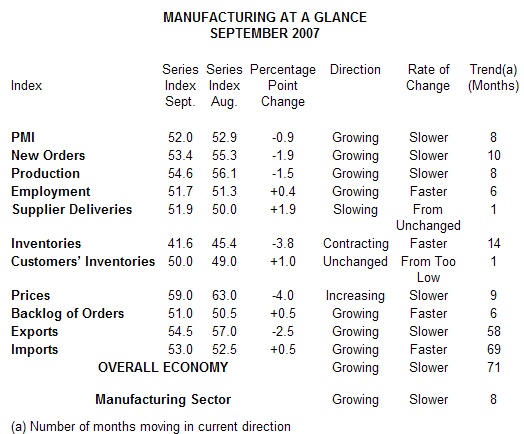

PMI

Manufacturing grew at a slower rate in September as the PMI registered 52 percent, a decrease of 0.9 percentage point when compared to August’s reading of 52.9 percent. A reading above 50 percent indicates that the manufacturing economy is generally expanding; below 50 percent indicates that it is generally contracting.

A PMI in excess of 41.9 percent, over a period of time, generally indicates an expansion of the overall economy. Therefore, the PMI indicates that both the overall economy and the manufacturing sector are growing. “The past relationship between the PMI and the overall economy indicates that the PMI average for January through September (53 percent) corresponds to a 3.4 percent increase in real gross domestic product (GDP) annually. In addition, if the PMI for September (52 percent) is annualized, it corresponds to a 3.1 percent increase in real GDP annually.”

New Orders

ISM’s New Orders Index registered 53.4 percent in September. The index is 1.9 percentage points lower than the 55.3 percent reported in August. A New Orders Index above 49.1 percent, over time, is generally consistent with an increase in the Census Bureau’s series on manufacturing orders (in constant 2000 dollars). Ten industries reported increases during September: Apparel, Leather & Allied Products; Petroleum & Coal Products; Electrical Equipment, Appliances & Components; Plastics & Rubber Products; Food, Beverage & Tobacco Products; Miscellaneous Manufacturing; Nonmetallic Mineral Products; Paper Products; Chemical Products; and Computer & Electronic Products.

Production

ISM’s Production Index registered 54.6 percent in September, which is 1.5 percentage points lower than the 56.1 percent reported in August. September is the eighth consecutive month of production growth for manufacturers. An index above 49.8 percent, over time, is generally consistent with an increase in the Federal Reserve Board’s Industrial Production figures. Of the industries reporting in September, 13 registered growth: Petroleum & Coal Products; Apparel, Leather & Allied Products; Electrical Equipment, Appliances & Components; Paper Products; Wood Products; Miscellaneous Manufacturing; Plastics & Rubber Products; Nonmetallic Mineral Products; Food, Beverage & Tobacco Products; Chemical Products; Fabricated Metal Products; Computer & Electronic Products; and Transportation Equipment.

Employment

ISM’s Employment Index registered 51.7 percent in September, which is an increase of 0.4 percentage point when compared to August’s reading of 51.3 percent. An Employment Index above 49.2 percent, over time, is generally consistent with an increase in the Bureau of Labor Statistics (BLS) data on manufacturing employment. The seven industries reporting growth in employment during September are: Petroleum & Coal Products; Apparel, Leather & Allied Products; Nonmetallic Mineral Products; Transportation Equipment; Food, Beverage & Tobacco Products; Machinery; and Fabricated Metal Products.

Supplier Deliveries

The delivery performance of suppliers to manufacturing organizations increased 1.9 percentage points in September as the index rose to 51.9 percent, indicating slower deliveries when compared to August. A reading above 50 percent indicates slower deliveries. The seven industries reporting slower supplier deliveries in September are: Printing & Related Support Activities; Electrical Equipment, Appliances & Components; Chemical Products; Computer & Electronic Products; Food, Beverage & Tobacco Products; Machinery; and Fabricated Metal Products.

Inventories

Manufacturers’ inventories registered 41.6 percent in September, which is 3.8 percentage points lower than August’s reading of 45.4 percent. This is the 14th consecutive month of inventory liquidation and the lowest reading since January 2007 when the index registered 39.9. An Inventories Index greater than 42.4 percent, over time, is generally consistent with expansion in the Bureau of Economic Analysis’ (BEA) figures on overall manufacturing inventories (in chained 2000 dollars). The three industries reporting higher inventories in September are: Textile Mills; Printing & Related Support Activities; and Nonmetallic Mineral Products.

Customers’ Inventories(b)

The ISM Customers’ Inventories Index registered 50 percent in September indicating no change from August. The index indicates that respondents believe their customers’ inventories are neither too high nor too low at this time. Six industries reported higher customers’ inventories during September: Furniture & Related Products; Fabricated Metal Products; Transportation Equipment; Food, Beverage & Tobacco Products; Chemical Products; and Computer & Electronic Products.

Prices(b)

In September, the ISM Prices Index registered 59 percent, indicating manufacturers are paying higher prices on average when compared to August. While 30 percent of respondents reported paying higher prices and 12 percent reported paying lower prices, 58 percent of supply executives reported paying the same prices as the preceding month. A Prices Index above 47.2 percent, over time, is generally consistent with an increase in the Bureau of Labor Statistics (BLS) Index of Manufacturers Prices. In September, eight industries reported paying higher prices: Food, Beverage & Tobacco Products; Plastics & Rubber Products; Textile Mills; Printing & Related Support Activities; Furniture & Related Products; Chemical Products; Paper Products; and Transportation Equipment.

Backlog of Orders(b)

ISM’s Backlog of Orders Index registered 51 percent in September, 0.5 percentage point higher than the 50.5 percent reported in August. Of the 84 percent of respondents who reported their backlog of orders, 24 percent reported greater backlogs, 22 percent reported smaller backlogs, and 54 percent reported no change from August. The eight industries reporting an increase in order backlogs in September are: Apparel, Leather & Allied Products; Electrical Equipment, Appliances & Components; Paper Products; Furniture & Related Products; Plastics & Rubber Products; Chemical Products; Food, Beverage & Tobacco Products; and Machinery.

New Export Orders(b)

ISM’s New Export Orders Index registered 54.5 percent in September, a decrease of 2.5 percentage points when compared to August’s index of 57 percent. This is the 58th consecutive month of growth in export orders. The 10 industries reporting growth in new export orders in September are: Apparel, Leather & Allied Products; Nonmetallic Mineral Products; Furniture & Related Products; Electrical Equipment, Appliances & Components; Transportation Equipment; Miscellaneous Manufacturing; Computer & Electronic Products; Chemical Products; Food, Beverage & Tobacco Products; and Machinery.

Imports(b)

Imports of materials by manufacturers grew during September as the Imports Index registered 53 percent, 0.5 percentage point higher than the 52.5 percent reported in August. This is the 69th consecutive month of growth in import orders. The eight industries reporting growth in import activity for September are: Apparel, Leather & Allied Products; Nonmetallic Mineral Products; Transportation Equipment; Plastics & Rubber Products; Furniture & Related Products; Miscellaneous Manufacturing; Chemical Products; and Computer & Electronic Products.

(b) The Backlog of Orders, Prices, Customers’ Inventories, Imports and New Export Orders Indexes do not meet the accepted criteria for seasonal adjustments.

Buying Policy

Average commitment leadtime for Capital Expenditures increased 15 days to 125 days. Average leadtime for Production Materials decreased 1 day to 47 days. Average leadtime for Maintenance, Repair and Operating (MRO) Supplies increased 2 days to 26 days.